Printing Progress: Perfecting our Pi Wars Podium Prospect

From CAD to Reality: Refining Our 3D-Printed Chassis for Pi Wars Glory

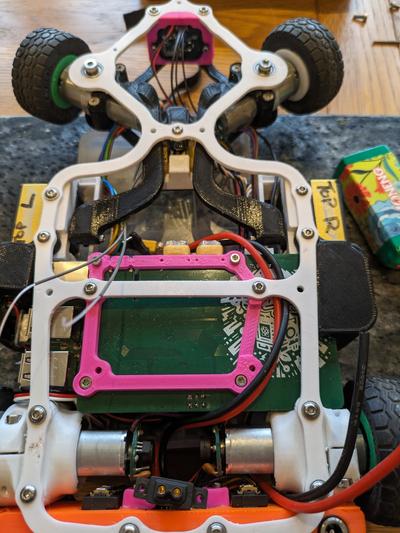

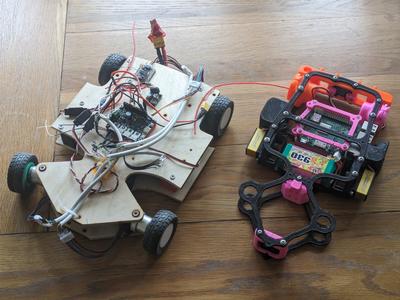

Following the completion of our CAD design, we’ve taken the exciting step of 3D printing our new chassis design for the Pi Wars robot. This phase brought our digital blueprints to life, allowing us to conduct a test assembly that was both revealing and invaluable. While the initial assembly showed promising results, we identified several areas needing refinement to ensure our robot is battle-ready.

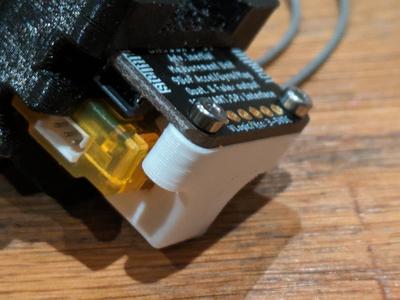

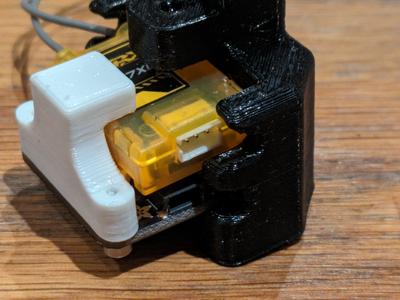

We discovered that the chassis, although quite flexible on its own, became robust once fully assembled, yet still offered the slight suspension we hoped for. However, challenges like the battery holder’s fragility and size mismatches, orientation issues leading to part weaknesses, and the need for additional structural support were noted. Adjustments include redesigning components for strength, ensuring clearances for easy assembly and maintenance, and incorporating specific features for stability and wire management.

This iteration process is crucial, highlighting the adaptability and resilience of our design philosophy. Each identified issue has been addressed, reinforcing our commitment to innovation and precision. As we refine our robot, we’re reminded of the journey’s importance, not just the destination. Stay tuned for more updates as we continue to evolve our design towards Pi Wars 2024.